By Mike Loughrin, CEO for Transformance Advisors

The Magical Word

Put the word “strategic” in front of any process and, like magic, it becomes much more important.

Sometimes, it becomes so important that common folk can no longer be allowed to know exactly what it means!

And even worse, everyone assumes the very important process is aligned with the company strategy. How can it not be when the word strategic is tossed around with such great reverence?

Let’s explore “strategic sourcing” as an example where confusion reigns and the link to strategy is often lost in the rush to find suppliers and keep things flowing through your supply chain.

Two Common Strategic Sourcing Definitions

Let’s take a look at two definitions of strategic sourcing:

- “Finding and developing long term relationships with suppliers who account for a large percentage of an organization’s spending and/or provide critical goods or services.”

- “A systematic and fact‐based approach for optimizing an organization‘s supply base and improving the overall value proposition.”

For the first definition, the key words are long term relationships, large percentage of spending, and critical goods or services.

Though it specifies long term relationships, it seems that many companies have strategic sourcing people called “commodity managers” who are encouraged to keep switching suppliers in search of the lowest purchase price. This approach to frequent supplier changes is not at all what strategic sourcing is about.

For the second definition, the emphasis is on using a systematic and fact‐based approach to improve the overall value proposition.

A key word here is value, as opposed to purchase price. We all know sourcing based upon the lowest price, without consideration of other factors, often leads to higher total costs.

Using purchase price variance as a performance measurement is one the most foolish things you can do!

Let’s take a closer look at the key words in the two definitions:

Long term relationships

Strategic sourcing is definitely not about 1 order, 1 quarter, or even 1 year. Though any of these may seem a very long time to people that cannot bear to make a commitment.

The entire life cycle of a product or service is moving closer to long term and may reach 5 to 10 years. Multiple generations brings to mind the concept of a life-time customer – which for our purposes would be choosing a life-time supplier.

An early example of this is Henry Ford, who purchased tires from Harvey Firestone, and head lamps from Thomas Edison, who founded GE. These three legends grew the automotive industry and were also friends who had winter homes near one another in Florida.

Large Percentage of Spending

Vilfredo Pareto was an Italian economist in the late 19th century. The Pareto principle is based upon his observation that 80% of the wealth in Italy was owned by 20% of the population. This concept is also known as the 80-20 rule.

In terms of strategic sourcing, the emphasis needs to be on those critical goods and services that make up a large percentage of your total expenditures.

You should create a Pareto analysis of your spending to identify the top 20% of the items that make up 80% of your total spending.

Critical Goods or Services

Besides those items making up a large percentage of spending, there may be other items requiring special care because they are critical to your organization.

In terms of physical goods, examples include special ingredients, complex processing requirements, intellectual property considerations, potential for disruption, and goods with few supply options.

In terms of services, examples include ERP systems, logistics providers, marketing and brand development, intellectual property considerations, energy, and services with few supply options.

Yes, an order can be lost when you cannot print a contract for the customer to sign. But, don’t be silly and classify printers, toner, and paper as critical goods that must be included in your strategic sourcing process. If everything is strategic, then nothing is strategic.

Systematic and Fact‐based Approach

Strategic sourcing should be very systematic; facts need to drive the decisions.

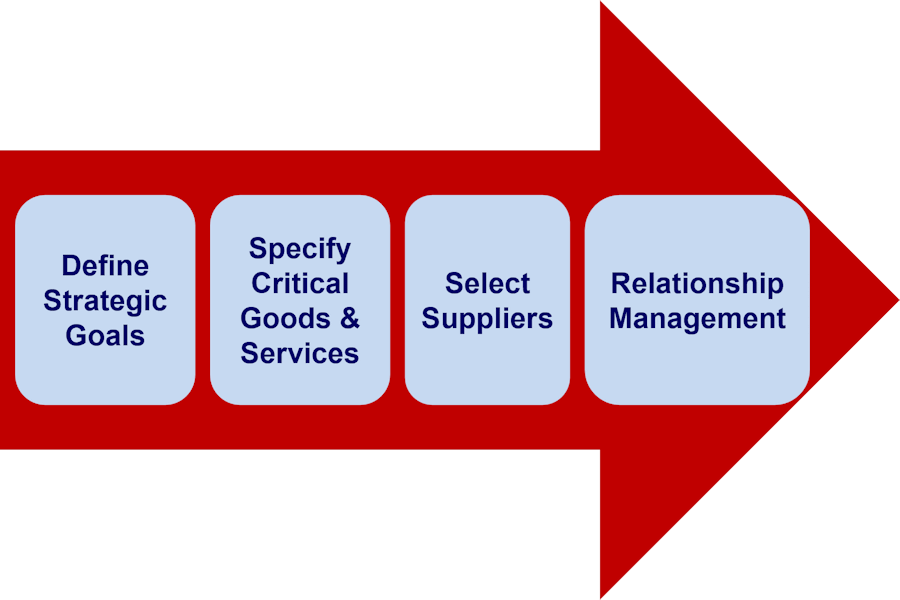

Four steps form the essence of a systematic process:

- Define Strategic Goals: What are the strategic organizational goals that must to supported? Where is alignment needed in terms of your core strategy, network strategy, strategic initiatives, social responsibility commitments, and other strategic decisions? More to come on this topic in a future article.

- Specify Critical Goods and Services: What are the items making up that large percentage of spending? What are the other items requiring special care? Then, item by item, what are the strategic goals you need to align with during the next step when you evaluate and select suppliers? More to come in a future article.

- Select Suppliers: Using your specifications for each critical good and service, find and establish relationships with suppliers. See article on Successful Supplier Selection.

- Relationship Management: Maintain and improve your relationship with each supplier of critical goods and services. More to come in a future article.

Overall Value Proposition

The focus must be on Total Landed Cost or the even greater analysis called Total Cost of Ownership.

For strategic sourcing, total landed cost includes all costs associated with making and delivering products and services to your point of use. These costs include purchase price + transportation costs + handling costs + duties, tariffs, and taxes + broker fees + documentation + financial transaction costs + inventory carrying costs + rework and damage costs + expediting costs + customer service penalties + a number of other factors.

Total Cost of Ownership adds the additional costs occurring after your point of use. These costs include factors such as installation, operation, supplies, maintenance, repairs, user fees, annual fees, and end-of-life.

The pursuit of lower purchase price vs. total cost of ownership is the cause for many of the disasters we see in the news day after day.

Back To Those Strategic Sourcing Definitions

Two definitions of strategic sourcing have supported a good part of this article.

I’m not sure how you feel, but I was not thrilled that it took two separate definitions to get enough substance to begin the discussion. In addition, neither definition provided any notion of the need for direct alignment with strategic goals. One definition used “optimizing,” but that’s an overused and misunderstood word that I choose to avoid.

It’s time to rebel against the status quo, stop the madness, and craft a better definition!

I propose the following:

Strategic sourcing is the systematic process to secure critical goods and services in a manner that is aligned with the strategic objectives of the organization. It will leverage long term relationships with suppliers and achieve the best total cost of ownership.

Mike Loughrin is the CEO and Founder of Transformance Advisors. He also teaches for Louisiana State University Shreveport and is on the board of directors for the Association for Supply Chain Management Northern Colorado.

Mike brings exceptional experience in industry, consulting services, and education. He has directed several Lean Transformation programs and has helped organizations such as Levi Strauss, Warner Bros., Cabela’s, Constellation Brands, Lexmark, CoorsTek, and Sweetheart Cup.

Keeping a commitment to a balanced life, Mike loves downhill skiing, bicycle rides, and hiking in the mountains. See one of his trails of the month at: Little Switzerland.

Global Sourcing

Supplier Scorecards

Successful Supplier Selection

Putting Strategy into Sourcing

What is Supply Chain Management?

Subscribe to our newsletter

References

Organizational Improvement Acronyms by Transformance Advisors

Organizational Improvement Definitions by Transformance Advisors

Why Companies Should Consider Strategic Sourcing by Michigan State University