By Mike Loughrin, CEO for Transformance Advisors

Easy Picking

It’s time to explore a concept which will make the charlatans angry. I can hear them now: “you can’t tell people to ignore the low hanging fruit and the quick wins which come from the easy opportunities”.

Don’t get me wrong. I love grabbing the quick wins. I am not telling anyone to ignore the low hanging fruit.

But, I have seen too many improvement programs stall out. I have seen too many “smart” people run failing projects because their skills are dull and they don’t even know it.

Why do improvement programs seem to stall at the very moment “success after success” points to great potential?

Could those successful projects, focused on the low hanging fruit, have planted the seeds of failure?

If you are like me, then you know that feeling which comes when everything seems to be too easy.

“If it seems too good to be true, then it probably is.”

– Process Improvement Champion from 1580

Great Start

Most improvement programs, such as Lean or Six Sigma, will get off to a fast start.

The common foundation for launching these programs includes:

- Top management has made the case for change

- Education brings new ideas and sharpens everyone’s skills

- Resources are in place and eager to show results

- There is an abundance of low hanging fruit – opportunities are everywhere

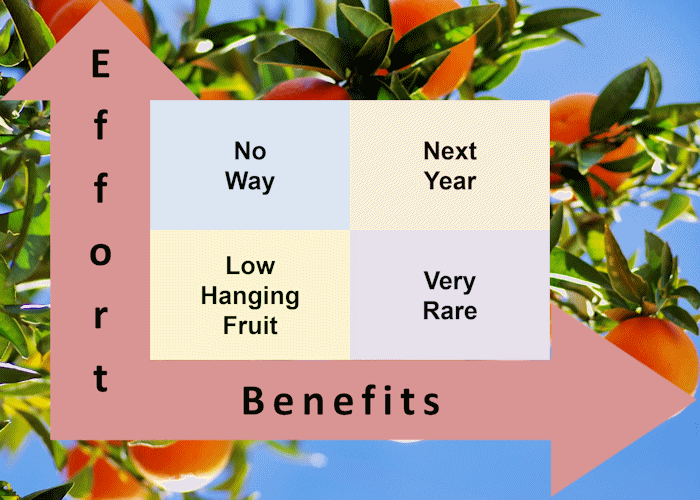

It’s common for a new improvement program to assess the many opportunities for early projects. Everyone wants to start strong with an early success.

Looking in terms of benefits and effort, you find the low hanging fruit delivers nice benefits for minimal effort. These opportunities are the perfect place to start.

But, buried in the very DNA of those early projects is a genetic disease waiting to strike!

Natural Tendancy

Picking the low hanging fruit is fast, fun, and rewarding. It also allows you to delay those challenging projects which require you to be at the top of your game.

Of course, it is a wise decision to go after the easy and rewarding opportunities.

Just recognize how playing tic-tac-toe does not prepare you for the competition of a high stakes poker tournament.

Given “easy” projects which deliver nice benefits, you don’t need to exercise the skills you learned in those certification courses. A muscle, which is not used, will grow weak. And problem solving skills, which are not used, will become dull.

It’s normal for educational events to explore the correct approach for using various problem solving tools. And it’s also normal for people to only use the parts of each tool they need for solving the easy projects. The critical steps for solving hard problems go unused and fade from memory.

Common Scenarios

Think about all the possibilities for your problem solving skills to become dull from lack of use:

- Don’t follow all of the steps for creating a value stream map – cut corners and move fast

- Skip the step to explore best practices – someone said we have the smartest people and don’t need to look elsewhere for ideas

- Just toss everyone into a room and run a kaizen blitz event – no need for the facilitator to waste time getting prepared

- Don’t bother with a project charter – we don’t have time to scope out a project or get the right resources

- There’s not time to ask customers what they need – we already know what they want

- New people can get up to speed on the run – we hire the best and expect them to know everything they need

- A few people have complained about statistics – let’s drop the math and go with our instincts

- No need for a project champion – the boss is busy and everyone already knows what to do

- Let’s not waste time doing an annual review of our improvement program – it’s going great and everyone knows it

- Just work the first three steps from The 5S System – someone else might circle back around and do the last two steps at a later date

“My boss and our facilitator got into an argument about the scope of our project and who was in charge. It was clear we were headed for disaster.”

– Victim of a failing Lean Transformation

“I was thrown onto a Six Sigma project without any idea about what was going on. Eventually, the project was cancelled and someone gave all of us a yellow belt certificate.”

– Victim of a failing Six Sigma program

Out Of Steam

As most could predict, the reliance on picking low hanging fruit will lead to problems when you are faced with more difficult challenges.

Everyone knows you can easily cut yourself from a dull knife. You need more force to make a cut and are more likely to have an accident.

For an improvement program, dull skills lead to project failure, morale problems, and wasted time. In a worse case scenario, the entire program can quietly end. Another case of “been there, done that”.

Don’t blame yourself, or anyone else, if you find your skills have become dull. It’s simply time to up your game and sharpen the saw.

But don’t delay. A few failures can ruin your improvement program and send your career into the abyss.

“Negative results are just what I want. They’re just as valuable to me as positive results. I can never find the thing that does the job best until I find the ones that don’t.”

– Thomas Edison

Regaining Momentum

Transitioning from low hanging fruit to more challenging projects will require everyone to sharpen their skills.

One of the most common skills which people fail to exercise is the need to step back to reflect on your overall improvement program.

As something you have probably not done, or not done well, this activity should be enhanced to evaluate the skills which need to be sharpened.

A few things to consider:

- Assess recent project effectiveness – do you capture lessons learned at project closure?

- For all problem solving tools – what corners have you cut from the systematic approach you learned in those early classes?

- Be brutal on your use of project charters – what are you not doing well?

- Where is the morale of everyone – do people feel frustrated and suspect the improvement program will soon end?

- Have you applied the wrong tools – was a better approach ignored because no one remembered that better way?

- Who needs the standard education provided at the launch of the improvement program – have new people been trained?

- Do you need to get data collection and statistical analysis back into your efforts at finding the root cause?

- Who has simply forgotten too much and needs to retake the standard education provided at the launch of the improvement program?

- Does your team need more advanced training for moving your improvement program to the next level?

You will not sharpen the saw by just recognizing your skills are dull. It took more than a day to dig this hole and it will take more than a day to recover.

“Do not worry about your difficulties in mathematics. I can assure you mine are still greater.”

– Albert Einstein

Conclusion

All serious improvement programs begin with education and a burst of success from picking the low hanging fruit.

There is a natural tendency to apply skills at a level appropriate for the challenge you face. The easy projects, focused on low hanging fruit, will not require using all your skills or following all the steps you learned in a class.

At some point, skills become dull from lack of use. At the same time, projects become more difficult. Dull skills and difficult projects is a recipe for disaster.

The transition from easy projects to challenging ones is a dangerous time. Those with dull skills need to recognize their situation and implement a recovery plan.

“We must never become too busy sawing to take time to sharpen the saw.”

– Stephen R. Covey

Mike Loughrin is the CEO and Founder of Transformance Advisors. He also teaches for Louisiana State University Shreveport and is on the board of directors for the Association for Supply Chain Management Northern Colorado.

Mike brings exceptional experience in industry, consulting services, and education. He has directed several Lean Transformation programs and has helped organizations such as Levi Strauss, Warner Bros., Cabela’s, Constellation Brands, Lexmark, and Sweetheart Cup.

Keeping a commitment to a balanced life, Mike loves downhill skiing, bicycle rides, and hiking in the mountains. See one of his trails of the month at: Little Switzerland.

Project Champion Guidelines

What is Lean Transformation?

Team Effectiveness Assessment

What is Continuous Improvement?

Improvement Program Assessment

Subscribe to our newsletter

References

What is the Meaning of Low-Hanging Fruit in Business? by F. John Reh