By Mike Loughrin, CEO for Transformance Advisors

Reader Beware

It’s time for straight talk about 5S failures.

The kind of discussion which will be uncomfortable for some.

The kind of discussion which will get some people angry.

I will be called a fool and told to take a long hike on a short pier.

It’s time to challenge conventional wisdom about starting a Lean Transformation.

Those with weak hearts should not read any further!

The Contrarian Strikes

I was listening to a Lean charlatan the other day.

You the know type. They think they know it all and have all the answers. And yes, it’s easy to have all the answers when you never think deeply about the questions.

The charlatan was seeking to dazzle me with his wisdom that 5S is a fundamental element of all Lean programs and it needs to be the first thing everyone does.

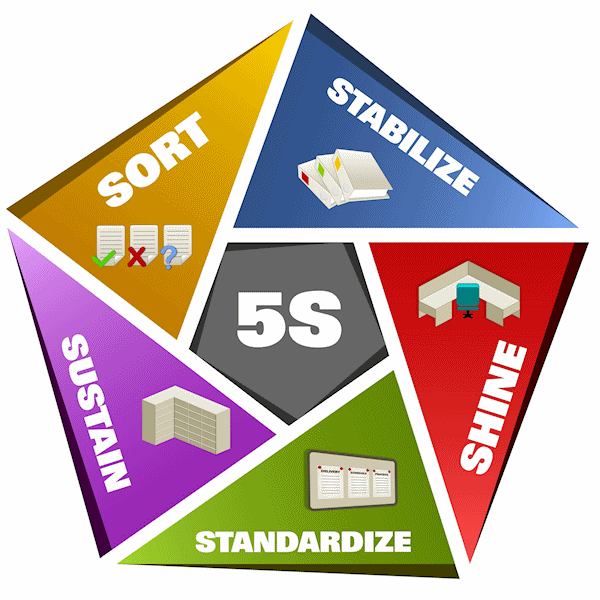

Most of us know The 5S System sounds very easy and powerful.

Most of us, who have tried to implement 5S, have been disappointed and amazed at the challenges.

The old joke proclaims: “it’s fun and easy to do The 3S System.” Yes, the first three steps – sort, stabilize (or straighten), and shine – are fun and easy.

It looks like time for me to be a contrarian and proclaim: “The 5S System should not be the first thing you do.”

I’m A Believer

Now don’t get me wrong.

I totally believe in The 5S System. But I have found the last 2 steps – standardize and sustain – are a real bear to tackle. Standardize includes the need for standard operating procedures and a process to keep these documents up to date. Sustain includes the need for a rigorous auditing process and the ability to find and fix the root cause of low scores from an audit. Both of these are much easier said than done.

During my journeys, I have found a vast majority of organizations have failed initially.

For many, implementing the standardize and sustain steps is not something their skills and culture are able to achieve initially. You need to be further into your Lean journey before the routine daily 5S activities become habits and are simply part of your standard operating procedures.

That’s just the way it works. This is not a failure of the tool or the people.

Repeat: that’s just the way it works.

While I have not taken a statistically valid sample – I’m going to put out a hypothesis: “95% of people fail at their first attempt to implement The 5S System.”

“5S was like a sugar high. It felt great for a week and then we crashed right back to where we started.”

– Victim of False Hope

What’s The Point

Back to the charlatan.

Why was he so sure 5S needs to be the first thing everyone does?

I got to thinking about how I never recommend 5S as the first thing to do.

Yes, I admit, I was listening and I was wondering if I needed to change.

But then, I thought about my hypothesis: 95% of people fail at their first attempt.

Why would anyone recommend you begin your Lean Transformation with a project which requires a big cultural shift and has a very small chance of success?

Go For A Win

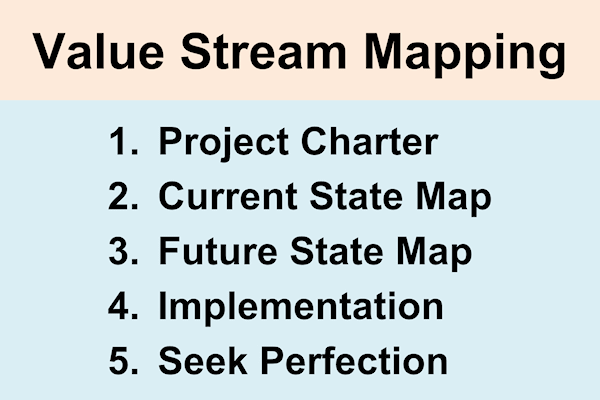

The better approach is to begin with a Lean project which provides hands-on experience and will deliver results.

Focus on building a foundation which includes:

- 5 Principles of Lean

- Types of Waste

- Value Stream Management

- Stakeholders Specify Value

- Continuous Improvement

- Education

- Employee Involvement

Achieving the above with your first Lean project and also delivering results seems like a great goal.

Plus, the proven path to achieve this is through a standard value stream mapping project.

You are leveraging an approach which has a far higher chance of success.

That’s my recommendation on where to start.

Summary

The 5S System is a great Lean tool. But the last two steps require an organization to live and breathe standardization and sustainability.

Don’t be fooled by the Lean charlatans who tell you 5S needs to be your first Lean project.

You don’t want to start your Lean Transformation with a failure.

Go for a win and leverage a value stream mapping project which will provide a much higher chance of success and a much higher return on investment.

Plus, if your current state map identifies disorganization and chaos, then do the 3S – it’s fun and easy!

Mike Loughrin is the CEO and Founder of Transformance Advisors. He also teaches for Louisiana State University Shreveport and is on the board of directors for the Association for Supply Chain Management Northern Colorado.

Mike brings exceptional experience in industry, consulting services, and education. He has directed several Lean Transformation programs and has helped organizations such as Levi Strauss, Warner Bros., Cabela’s, Constellation Brands, Lexmark, and Sweetheart Cup.

Keeping a commitment to a balanced life, Mike loves downhill skiing, bicycle rides, and hiking in the mountains. See one of his trails of the month at: Little Switzerland.

5 Horrors of Lean

All Wrong About 5S

Apply 5S To Your Life

Step 5 of The 5S System

Does Safety Begin With S?

Subscribe to our newsletter

References

What is 5S? by 5S Today

What is 5S? by Brian McFadden

Why Does 5S Fail Sometimes? by Creative Safety Supply

Organizational Improvement Acronyms by Transformance Advisors

Organizational Improvement Definitions by Transformance Advisors