By Ally Conrad, Events Manager for Transformance Advisors

Systematic 5 Step Process

Why is it that we keep reading more and more articles about companies failing due to their supplier selection process?

Let’s discuss the 5 steps you should take in order to make the correct decisions in supplier selection.

Keep in mind:

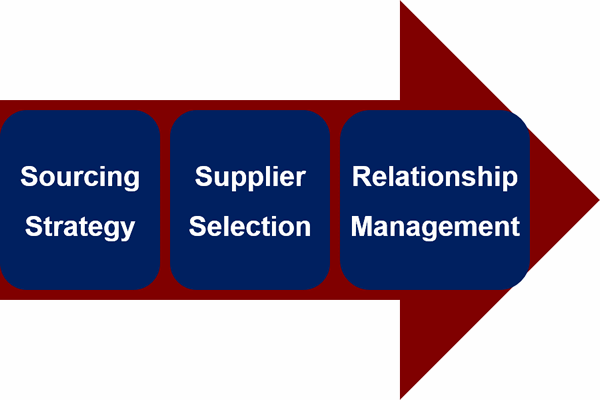

- An important input to the supplier selection process are the guidelines for the types of suppliers you want. These guidelines are impacted by your Sourcing Strategy; which we explored in What is Strategic Sourcing? and Putting Strategy into Strategic Sourcing.

- The output of the supplier selection process is creating your first order for that lucky supplier. You will then move into the Relationship Management phase, which will be covered in a future article.

Step 1 – Supplier Selection Scorecard

The first step in the supplier selection process is to create a supplier selection scorecard.

The supplier selection scorecard contains all the important elements you require in a supplier. It has long been stated: “that which does not get measured, does not get done”.

Your scorecard should be quantifiable and include:

- Supplier characteristics

- The important strategic alignment factors you value

- Applicable business policies

- Any constraints, suc as management directives, government regulations, contracts already in place, and other commitments

At this step, make sure you are prioritizing your needs. All of the above may be important but some are more important than others.

For example, quality may be most important. Surprising to some, cost is often a low priority. If a supplier offers poor quality, long lead time, and late deliveries, then does it really matter how low the price is?

Supplier Characteristics

| Cost | Reputation |

| Quality | Certifications |

| Delivery | Collaboration |

| Location | Customer Base |

| Capacity | Financial Health |

| Flexibility | Social Responsibility |

| Lead Time | Product Development |

Step 2 – Identify Suitable Suppliers

Once you have the selection criteria in place, you must create the pool from which you will select a supplier. During this part of the process, you will want to consider:

- Current suppliers – Starting with suppliers you have experience with and established relationships is generally a good idea

- Past suppliers – Depending upon the reasons why they are ‘past’ and not ‘current’

- Competitors – You may be in a position to buy from a competitor if it is ethical and low-risk

- Industry groups – many of which are non-profit and maintain data bases of member companies

- Recommendations and prior business relationships – perhaps created while working at other companies

- Internet searches – the world is available for you to find, research, and contact potential suppliers

- Artificial Intelligence – a very promising approach for leveraging the exploding technology

Step 3 – Scorecard Ranking

Next, gather information from the identified suitable suppliers – perhaps in the form of a Request for Quote (RFQ) or Request for Proposal (RFP).

Tabulate the information you collect and use the scorecard to rank the potential suppliers.

Depending upon the complexity and/or criticality of the product or service, you may:

- Select the highest ranking supplier. Recognize that while you are not required to pick the top scorer, moving too far down the list is a red flag, indicating the process was flawed.

- Choose more than one for further qualification. You might want to conduct interviews, make site visits, or contact references.

If all that work did not identify a clear winner, then you may need to review your criteria and/or expand your search.

Step 4 – Negotiate

After you have narrowed the list to a manageable number of best options, possibly just one, let the negotiations begin!

Depending on the critical good or service, you may negotiate with just the top supplier on your scorecard, even if others remain on the list of potentials.

These others, of course, are not told they are not #1 until after you have completed negotiations and agreements are completed.

Based upon the complexity of the situation, lawyers may be involved.

Step 5 – Create Contract

Once an agreement is reached, a contract is created and signed.

For many transactions, the purchase order is the contract. For complex situations, you may have a contract and then create a separate purchase order.

Creating the purchase order will include activating your procurement system. This should be a standard operating procedure and include getting your accounts payable process ready to process the supplier invoice.

Supplier Selection Summary

When you strategically think about each supplier in your network and invest time to examine all your options, you will set your organization up for success.

To create a network that is strong, reliable, and aligned with your business objectives; utilize this 5 step process:

- Create supplier selection scorecard

- Identify suitable suppliers

- Rank the scorecard

- Negotiate

- Create contract

Global Sourcing

Supplier Scorecards

Critical Goods and Services

What is Strategic Sourcing?

What is Supply Chain Management?

Subscribe to our newsletter

References

What is Supply Chain Management? by Robert Handfield, Ph.D.

Organizational Improvement Acronyms by Transformance Advisors

Organizational Improvement Definitions by Transformance Advisors